+86 311 85258258

+86 311 85258258

Inspection will be implemented during the whole process from material mixing, molding, melting, raw casting grinding and cleaning, machining and stocking. Air pressure test or hydraulic pressure test will be made for some pressure bearing parts.

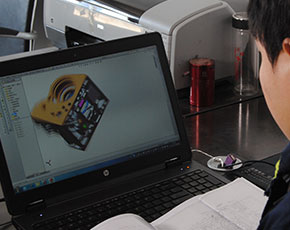

For many years, Zen Young Foundry has been providing customized metal casting services for various industries and project types.

Mining Engineering Machinery Casting Parts

If you are looking for a solution that fits your custom metal casting project, Zen Young can help you produce perfect metal parts through a reliable casting process.

We always welcome special material and difficult parts and would like to help our comstomers utmost.

Investment casting is one of the traditional casting methods. That is, the metal is heated to the temperature of the molten liquid, and then the material is poured into a mold designed with a suitable negative space and gated to effectively completely fill the molten metal. Once the metal has cooled and solidified, the metal part can be removed from the mold for finishing. Investment casting, also known as lost wax casting, is usually used to make jewelry and metal parts with complex shapes.

The material used to make molds for sand casting is sand, not ceramics. Due to the roughness of sand, sand casting is most commonly used for large castings, which usually require less detail precision and tolerances.

Die casting is a kind of metal casting process, which is characterized by forcing molten metal under high pressure into the forming cavity. The cavity is made using two hardened tool steel molds, which have been processed into a certain shape, and die casting works similarly to injection molds.

We will choose different casting methods for processing according to the product shape, material and your working conditions. Many years of processing experience can guarantee the quality of the casting parts.