+86 311 85258258

+86 311 85258258

WELCOME TO ZEN YOUNG

Specialized in foundry technologies and solutions for worldwide manufacturers of pump, valve, electric motor, compressors, etc. We supply various castings and mechanical parts for various industries.

Zen Young's foundries implement investment casting,sand casting,and lost foam casting processing.

The investment casting foundry covers an area of around 30000m2 with 110 employees. Following the standardized production of ISO 9001:2015,we can handel material in stainless steel, bronze, aluminium,carbon steel, low alloy steel, non ferrous alloys,like 304,316 Stainless steel, CD4MCu,CA6NM,SS420,etc. Our products serve the industries like pump&valve,automobile, food, chemical, pharmacy, airplane and aerospace and so on.

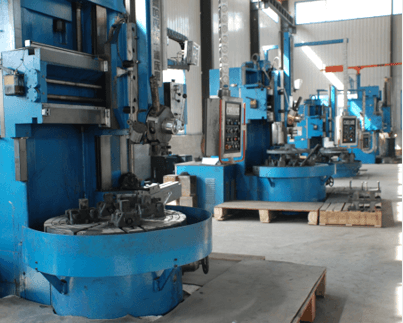

The sand casting foundry occupis over 130.000 m2, facilitated with a resin-sand processing line, a disa line and a 5 tons electric furnace, CNC lathes, CNC milling machines, CNC boring machines, CNC machining centers, heavy- duty lathes, vertical lathes, vertical drilling machines, etc.The foundry is able to cast parts weight from 0.1kgs up to 10,000kgs, to machine size up to 1600mm( rotating diameter). Annual output exceeds 10000 tons including all kinds of material like grey iron GG15, GG20, GG25, GG30, ductile iron GGG400-18, GGG500-7, GGG600-3, and GGG700-2, high-Chrome cast iron KmTBCr26, high-nickle casting iron D-5S, and also Austempered Nodular Iron. We can also supply wear-resistant alloy, like high manganese cast steel, for oil,mining and metallurgy industries. These high quality alloy parts provide our customers with longer wear life and improved efficiency.

With strict quality control system, and top chemical and metallurgical laboratory facilities, like spectrometer, ultrasonic detector, universal material tester, metallographic analyzer and CMM, we can ensure the exact material quality and standard as well as mechanical properties.

Our aim is to realize further studies of modernization and to be a "brand" in the international market with "Quality", "Reliability", "Zero defect policy" and "on time deivery" strategy.

Sincerely welcome your visit and cooperation!

Zen Young--Casting your future!

With strict quality control system, and top chemical and metallurgical laboratory facilities, like spectrometer, ultrasonic detector, universal material tester, metallographic analyzer and CMM, we can ensure the exact material quality and standard as well as mechanical properties.

Our aim is to realize further studies of modernization and to be a “brand” in the international market with “Quality”, “Reliability”, ”Zero defect policy” and “on time deivery” strategy.

“ Sincerely welcome your visit and cooperation! ”

OUR FACTORY

The sand casting process involves the use of a furnace, metal, pattern, and sand mold. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a parting line and the solidified casting can be removed. The six steps of the sand casting process are; placing the mold in pattern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break open the mold to remove the casting.

Investment casting is often referred to as "lost-wax casting" because the wax pattern is melted out of the mold after it has been formed.Investment casting requires the use of a metal die, wax, ceramic slurry, furnace, molten metal, and any machines needed for sandblasting, cutting, or grinding. The process steps include the following:Pattern creation,Mold creation,Pouring,Cooling,Casting removal and finishing.

We adopt CNC lathes, CNC milling machines, CNC boring machines, CNC machining centers, heavy- duty lathes, vertical lathes, vertical drilling machines, machine size can be up to 2500mm( rotating diameter), and tolerance +/0.01mm can be guaranteed.

With strict quality control system, and top chemical and metallurgical laboratory facilities, like spectrometer, ultrasonic detector, universal material tester, metalographic analyzer and CMM, we can ensure the exact material quality and standard as well as mechanical properties.

We adopt wooden cases or other seaworthy packages required by the buyers.

In stocking, we have unique “Kanban” Stocking system, every individual parts was positioned on a specific location one the shelf in the warehouse, and with the correspondence in the computer system, it can be found in one second.