+86 311 85258258

+86 311 85258258

Jul. 20, 2020

1. The working principle of the gearbox

The Reducer Housing is generally used for low-speed and high-torque transmission equipment. The power of the electric motor, diesel engine, or other high-speed running is achieved by meshing the gear with a small number of teeth on the input shaft of the reducer and the large gear on the output shaft. For the purpose of deceleration, ordinary gearboxes will also have several pairs of gears with the same principle to achieve the ideal deceleration effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.

Cast iron Reducer Housing mainly reduces speed and increases torque. There are many types, different models, and different types have different uses. There are many types of gearboxes, which can be divided into gearboxes, worm gearboxes, and planetary gearboxes according to the type of transmission; according to the number of transmission stages, they can be divided into single-stage and multi-stage gearboxes; according to the gear shape, they can be divided into cylindrical gear reducers. Boxes, bevel gearboxes, and conical-cylindrical gearboxes; according to the transmission arrangement, they can be divided into expandable, split, and coaxial gearboxes.

The first-stage cylindrical gear reducer realizes decelerating movement through the rotation of a pair of meshing gears installed in the box. The power is transmitted to the gear shaft by the motor through the pulley and then transmitted to the shaft through the two meshing gears (the small gear drives the large gear) to achieve the purpose of deceleration.

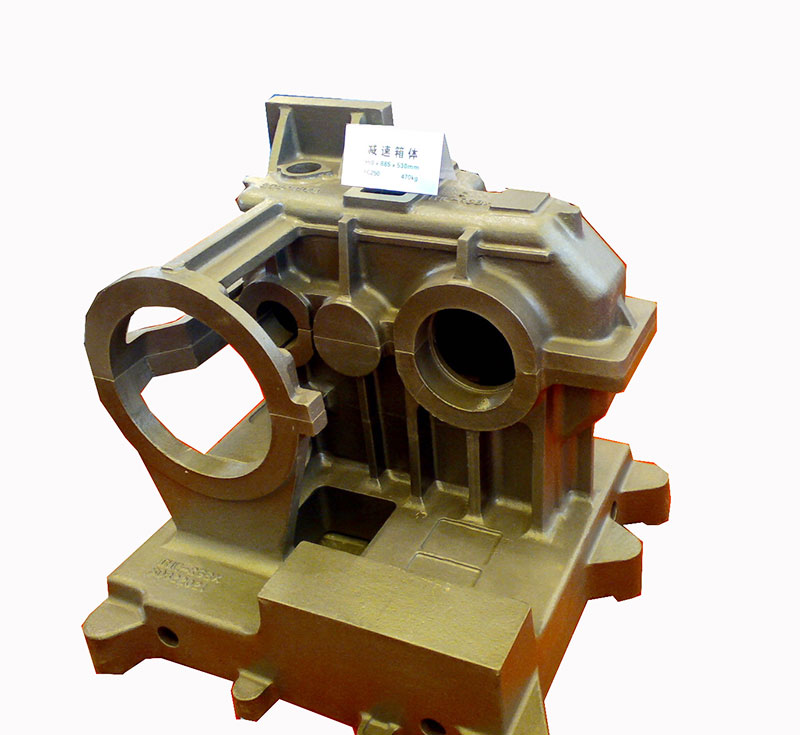

Reducer Housing

Second, the structure of the gearbox

Gear, shaft and bearing combination

The pinion and the high-speed shaft are made into one body, that is, the gear shaft structure is adopted. This structure is used where the gear diameter and shaft diameter are not much different. The big gear is assembled on the low-speed shaft, and the parts on the shaft are axially fixed by the shaft shoulder, sleeve, and bearing cap. Due to the axial component of the gear meshing, both shafts are supported by a pair of tapered roller bearings to bear the combined action of radial load and axial load. The bearing is lubricated with lubricating oil. In order to prevent the hot oil from the gear meshing from directly entering the bearing, an oil retaining ring is provided between the bearing and the pinion on the inner wall of the box in the bearing seat hole. In order to prevent the leakage of lubricant in the box at the junction of the shaft extension section and the bearing transparent cover, and the external dust and foreign matter from entering the box, the bearing transparent cover is equipped with a sealing element. The contact lip seal ring is used in the picture, which is suitable for dusty environments.

Box

The box body is an important component of the gearbox. It is the base of transmission parts and should have sufficient strength and rigidity. The box is usually cast with gray cast iron, and cast steel box can also be used for heavy reducers subject to impact loads.

Bearing cover and sealing device

In order to fix the axial position of the shaft system components and bear the axial load, both ends of the bearing seat hole are sealed with bearing caps. There are two types of bearing caps: flange type and embedded type. A flanged bearing cap is used. Use hexagonal screws to fix on the box. The bearing cover at the shaft extension is a through cover, and a sealing device is installed in the through cover. The advantage of flanged bearing caps is that it is more convenient to disassemble and adjust the bearing, but compared with embedded bearing caps, it has more parts, too large size, and not smooth appearance.

Positioning pin

In order to accurately process the bearing seat hole and ensure that the upper and lower half holes of the bearing seat will always maintain the position accuracy during processing after each disassembly and assembly, the connecting convex of the upper box cover and the lower box seat should be made before finishing the bearing seat hole. A positioning pin is fitted on the edge. The two positioning tapered pins are arranged on the coupling flanges on both sides of the longitudinal direction of the box body and are arranged asymmetrically to enhance the positioning effect.

In addition to the gearbox, our company has changed to provide other cast iron accessories, such as cast iron Electric Motor Housing, cast iron Gearbox, etc. If you are interested in our products, please feel free to contact us.