+86 311 85258258

+86 311 85258258

Copper casting works best with investment casting but sand casting and centrifugal casting is also available. The casting option for your project will depend on project volume, corrosion resistance requirements, regulations and specifications, and sizing requirements. We strive to deliver efficient, affordable copper based castings and services for every project.

Zen Young is your copper investment casting foundry for custom prototypes, ship propellers and plumbing fixtures and more. We can investment cast any part you require from copper-based alloys. Discover why customers trust us for all of their intricate and tight-tolerant needs when you order custom-cast copper-based parts.

Request a quote for the copper-based castings for your application.

There are several copper and copper-based casting materials, including brass, bronze, and beryllium copper.

Brass Castings: As the most popular copper-based castings, brass is a versatile material with a wide range of possible applications. Also known as red brass or yellow brass, this copper-based alloy is often used in plumbing, door hardware, and the drinking water industry. Brass castings have unique finishing qualities and are often polished to beautiful effect.

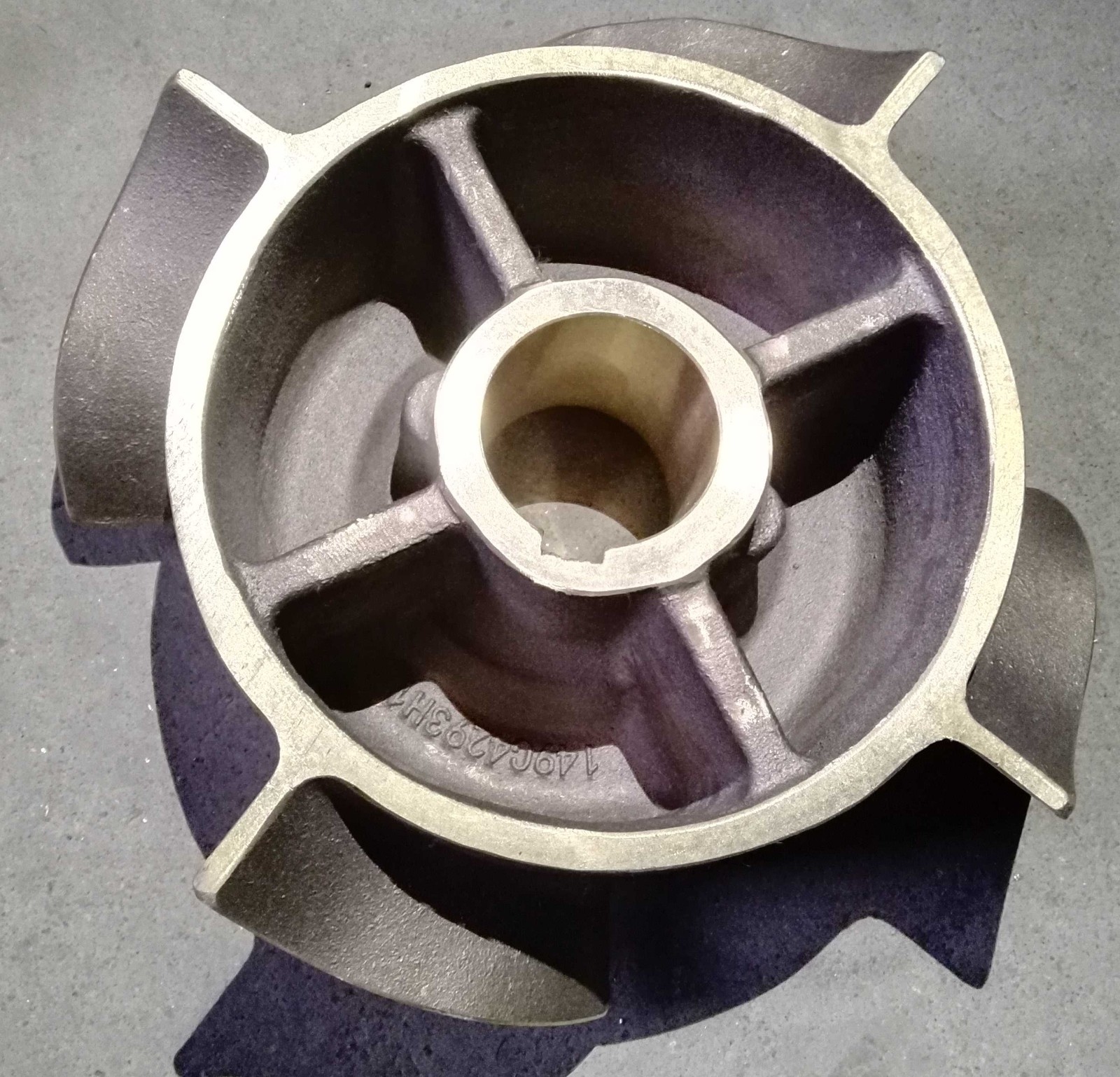

Bronze Castings: This copper-based alloy is commonly seen in small components such as bearings, which have a wide range of applications across the commercial and industrial sectors. While all bronze castings share similar properties, this alloy can be altered through the introduction of lead, aluminum, and tin just to name some elements.

Beryllium Copper Castings: This advanced and rather exotic copper alloy has a high strength component along with high thermal and electrical conductivity. This material is ideal for anyone who demands complex and high-precision shapes, with its refined appearance only matched by its durability and wear characteristics.

For many years, Zen Young Foundry has been providing customized metal casting services for various industries and project types.

Mining & Engineering Machinery Casting Parts

If you are looking for a solution that fits your custom metal Sand casting project, Zen Young can help you produce perfect metal parts through a reliable casting process. We always welcome special material and difficult parts and would like to help our comstomers utmost.

The material used to make molds for sand casting is sand, not ceramics. Due to the roughness of sand, sand casting is most commonly used for large castings, which usually require less detail precision and tolerances.

Shell mold casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable mold. However, in shell mold casting, the mold is a thin-walled shell created from applying a sand-resin mixture around a pattern. The pattern, a metal piece in the shape of the desired part, is reused to form multiple shell molds. A reusable pattern allows for higher production rates, while the disposable molds enable complex geometries to be cast. Shell mold casting requires the use of a metal pattern, oven, sand-resin mixture, dump box, and molten metal.

Investment casting is one of the traditional casting methods. That is, the metal is heated to the temperature of the molten liquid, and then the material is poured into a mold designed with a suitable negative space and gated to effectively completely fill the molten metal. Once the metal has cooled and solidified, the metal part can be removed from the mold for finishing. Investment casting, also known as lost wax casting, is usually used to make jewelry and metal parts with complex shapes.

Die casting is a kind of metal casting process, which is characterized by forcing molten metal under high pressure into the forming cavity. The cavity is made using two hardened tool steel molds, which have been processed into a certain shape, and die casting works similarly to injection molds.

Lost foam casting is a type of evaporative pattern casting. it maintains outstanding advantages, especially in casting complicated and precise molds.Unlike traditional methods which include the pattern withdrawn process before casting and require skillfulness in the pattern removal step, with respect to the lost foam method, the pattern is evaporated when the molten metal is poured into helping to reduce these considerations.

We will choose different casting methods for processing according to the product shape, material and your working conditions. Many years of processing experience can guarantee the quality of the casting parts.