+86 311 85258258

+86 311 85258258

Jan. 23, 2021

How To Choose Gray Iron, Ductile Iron, And Carbon Steel

What is the difference between gray iron, ductile iron, and carbon steel? You may need to know this information when choosing the right material for your casting products.

Cast iron is a metal with a carbon content of more than 2%. It can be divided into gray cast iron and ductile cast iron (also known as SG iron).

Carbon steel is a metal with a carbon content of less than 2%. If more alloying components are needed, such as Cr, Mo, Ni, or Cu, it will become alloy steel.

A) Their carbon content is the main difference.

B) Their material microstructure is different.

C) Their physical properties are different.

Grey cast iron. Black graphite is flaky, and when you see it in cross-section, it looks like strips.

Ductile iron. You can see a lot of black spherical graphite. The fracture stress of flake graphite is lower than that of flake graphite, which makes ductile iron better.

Carbon steel. Although they are not testes like, they are very small and have a special structure, so they have better mechanical properties.

Their different graphite structures cause their physical properties to differ greatly.

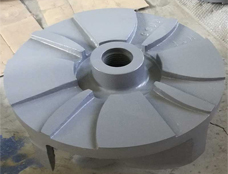

Grey cast iron has good casting properties, good vibration reduction, good wear resistance, good cutting ability, and low notch sensitivity. However, its tensile strength and elongation are very low, so grey cast iron is suitable for the production of some metal parts with low mechanical requirements.

Ductile iron has higher strength, better ductility, heat resistance, and toughness than gray iron, so it has a wide range of uses. In some cases, ductile iron can replace carbon steel.

Carbon steel has higher strength, very high ductility, and toughness, even better than ductile iron. The smelting process is relatively simple. It has good pressure machining performance, good cutting performance, and good mechanical properties. After proper heat treatment, they can meet many industrial production requirements.

Gray cast iron is the cheapest, and the price of ductile cast iron is higher than that of gray cast iron. If the sand casting process is used, the price of carbon steel may be similar to that of ductile cast iron, but if the investment casting process is used, the price of carbon steel may be higher.

If you would like a rough idea of their prices, please refer to cast iron prices per pound and kg and cast steel prices per pound and kg.

Gray iron and ductile iron are commonly produced by sand mold casting processes, including sand machine molding, shell molding (hot shell and core molding), and furan resin sand casting. Again, they can be made by the lost foam casting process.

Carbon steel can be produced by sand casting and lost-wax investment casting processes. The sand casting process can produce very large and heavy steel castings with poor surface quality. The lost-wax investment casting process can produce very small and complex castings, but at a much higher price than the sand casting process.