+86 311 85258258

+86 311 85258258

Jul. 08, 2020

There are many factors that affect the quality of metal casting, mainly divided into the following aspects:

The first is the design manufacturability of castings. When designing, in addition to determining the casting geometry and size according to working conditions and metal material properties, the rationality of the design must also be considered from the perspective of casting alloys and casting process characteristics, that is, obvious side effects and solidification and shrinkage, Stress and other problems to avoid or reduce the occurrence of defects such as segregation, deformation and cracking of the castings.

The second is to have a reasonable casting process. That is, according to the casting structure, weight, and size, casting alloy characteristics and production conditions, select the appropriate parting surface and modeling, core making method, and rationally set casting ribs, cold iron, riser and pouring system. To ensure access to high-quality castings.

The third is the quality of raw materials for casting. Substandard quality of metal charge, refractory materials, fuel, flux, modifier, foundry sand, molding sand binder, paint, and other materials will cause defects such as porosity, pinholes, slag inclusions, and sand stickiness in the casting, affecting the appearance quality of the casting And the internal quality will make the casting scrap when serious. The fourth is the process operation. It is necessary to formulate reasonable process operation regulations, improve the technical level of workers, and enable the process regulations to be correctly implemented.

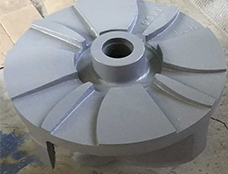

Mechanical Parts

The quality of castings has a great influence on the performance of mechanical products. Here are the problems and countermeasures of five kinds of metal castings:

Pin holes in metal castings

Measures to prevent pinholes: It is strictly forbidden to use contaminated cast aluminum alloy materials, materials contaminated with organic compounds and severe oxidation and corrosion; control the smelting process, strengthen degassing and refining; control the thickness of metal-type coatings, and excessive thickness may cause pinholes ; The temperature of the mold should not be too high, and quenching measures should be applied to the thick-walled parts of the casting, such as copper inlays or watering; when the sand mold is used, the moisture is strictly controlled and the dry core is used as much as possible.

Porosity often occurs in metal castings

Measures to prevent the occurrence of blowholes: Modify the unreasonable pouring riser system to make the liquid flow stable and avoid gas entrapment; the mold and the core should be preheated in advance, then coated, and must be dried before use after completion; design the mold With the core should consider sufficient exhaust measures.

Oxidative slag phenomenon often occurs in mechanical parts

Measures for preventing oxidation slag inclusion: strict control of the smelting process, rapid smelting, reducing oxidation, and thorough slag removal; Al-Mg alloy must be smelted under a covering agent; furnaces and tools must be clean, free of oxides, and should be preheated, paint It should be dried and used after coating; the designed pouring system must have the ability of steady flow, buffering and skimming; the inclined pouring system is used to make the liquid flow stable without secondary oxidation; the selected paint has strong adhesion and is not in the pouring process Peeling occurs and forms slag inclusions in the casting.

Hot cracking often occurs in metal castings

Measures to prevent the occurrence of thermal cracking: the actual pouring system should avoid local overheating and reduce internal stress; the slope of the mold and core must be above 2°, and the core can be pulled out to open the mold once the pouring riser is solidified, and the sand core can be used if necessary Replace metalcore; control the thickness of the paint to make the cooling rate of all parts of the casting consistent; select the appropriate mold temperature according to the thickness of the casting; refine the alloy structure to improve the thermal cracking ability; improve the structure of the casting to eliminate sharp corners and wall thickness mutations and reduce Hot cracking tendency.

Metal mold castings often appear loose

Measures to prevent loosening: reasonable riser setting to ensure its solidification and its ability to shrink; appropriately lower the working temperature of the metal mold; control the thickness of the coating, thinning at thick walls; adjust the cooling rate of each part of the metal mold so that there is a large chilling capacity at the thick wall of the casting; reduce the metal pouring temperature appropriately.